SOLL 2K EPOXY PRIMER BLACK 750ml Anti Corrosion Filler 2:1

SKU: S-EP 05B

£14.00

Availability: Only 10 left in stock

Next Day Available

Free delivery for orders above £150

1 Hour Click & Collect

At Leeds Store

CONTENTS

1x Epoxy Primer Black 0.5ltr

1x Hardener 0.25ltr

PRODUCT DESCRIPTION

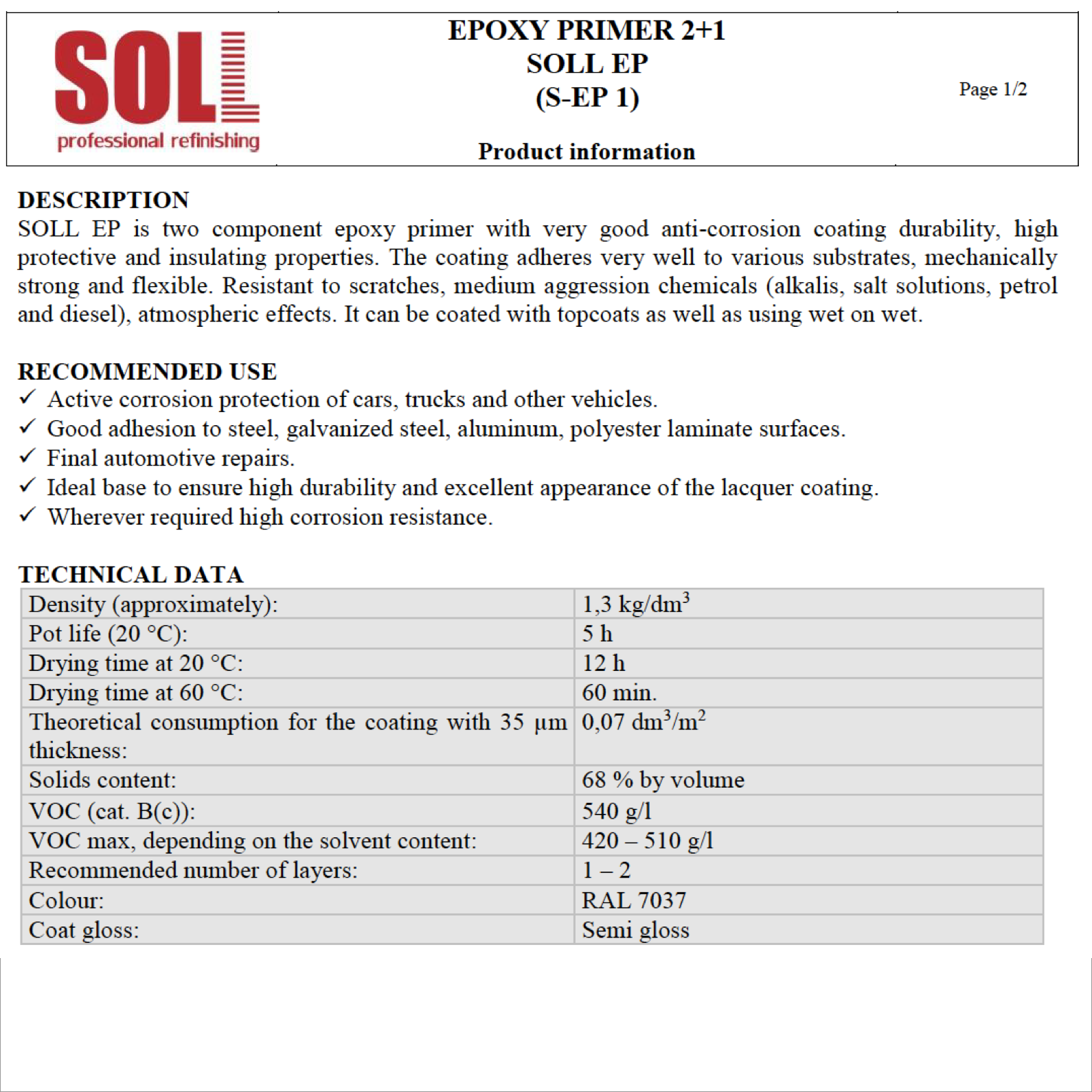

SOLL EP is two component epoxy primer with very good anti-corrosion coating durability, high protective and insulating properties. The coating adheres very well to various substrates, mechanically strong and flexible. Resistant to scratches, medium aggression chemicals (alkalis, salt solutions, petrol and diesel), atmospheric effects. It can be coated with topcoats as well as using wet on wet.

RECOMMENDED USE

Active corrosion protection of cars, trucks and other vehicles.

Good adhesion to steel, galvanized steel, aluminium, polyester laminate surfaces.

Ideal base to ensure high durability and excellent appearance of the lacquer coating.

Wherever required high corrosion resistance.

TECHNICAL DATA

Density (approximately): 1,3 kg/dm3

Pot life (20C): 5h

Drying time at 20C: 12 h

Drying time at 60C: 60 min.

Theoretical consumption for the coating with 35 ?m thickness: 0,07 dm3/m2

Recommended number of layers: 1?2

Coat gloss: Semigloss

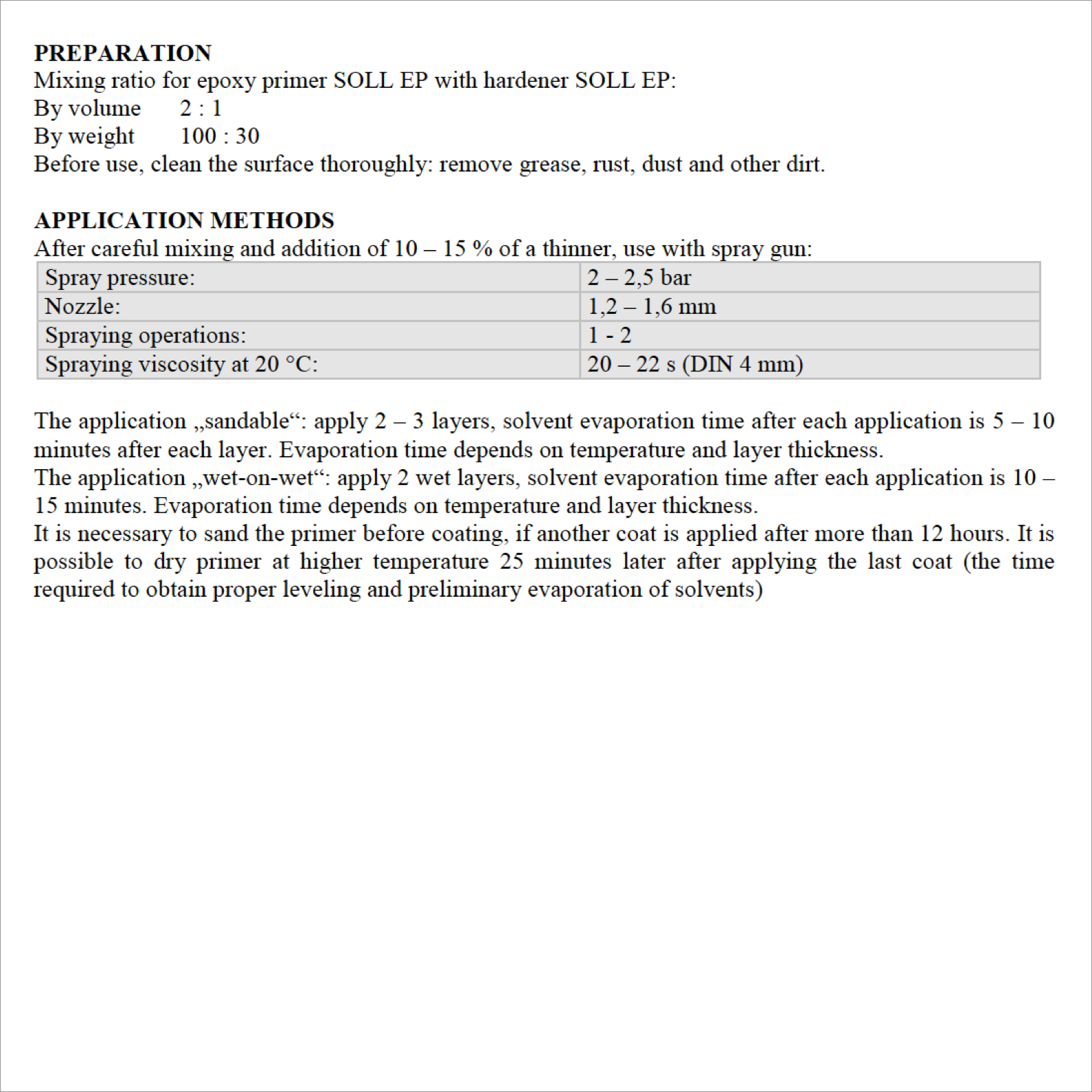

Mixing ratio for epoxy primer SOLL EP with hardener SOLL EP:

By volume 2 : 1

By weight 100 : 30

Before use, clean the surface thoroughly: remove grease, rust, dust and other dirt

APPLICATION

After careful mixing and addition of 10 – 15 % of a thinner, use with spray gun:

Spray pressure: 2 – 2,5 bar

Nozzle: 1,2 – 1,6 mm

Spraying operations: 1-2

Spraying viscosity at 20C: 20 ? 22 s (DIN 4 mm)

The application sandable: apply 2 – 3 layers, solvent evaporation time after each application is 5 – 10 minutes after each layer. Evaporation time depends on temperature and layer thickness.

The application wet-on-wet: apply 2 wet layers, solvent evaporation time after each application is 10 – 15 minutes. Evaporation time depends on temperature and layer thickness.

It is necessary to sand the primer before coating, if another coat is applied after more than 12 hours. It is possible to dry primer at higher temperature 25 minutes later after applying the last coat (the time required to obtain proper levelling and preliminary evaporation of solvents)

SANDING

Dry sanding P400 – P500 Wet sanding P800 – P1000

ADDITIONAL INFORMATION

Processing conditions: from + 5 ?C and up to 85 % relative air humidity.

| Weight | 1.4 kg |

|---|---|

| Primary Colour | |

| Country/Region of Manufacture | |

| Type | |

| Manufacturer Part Number | |

| Brand | |

| Volume | 750ml |

| Items Included | |

| Custom Bundle |